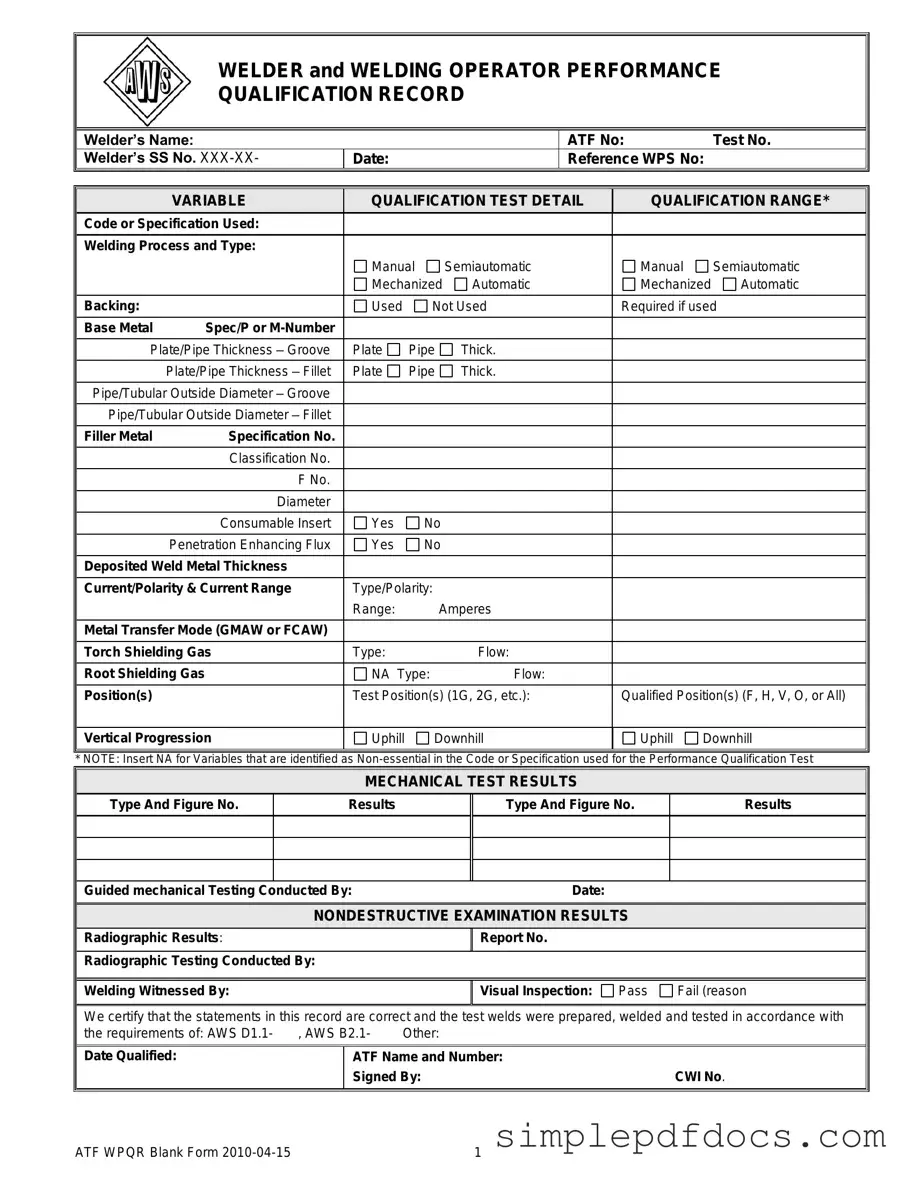

Fill Your Welder Performance Qualification Record Form

The Welder Performance Qualification Record form serves as a vital document in the welding industry, capturing essential information about a welder's skills and qualifications. This form includes critical details such as the welder’s name, social security number, and the specific test number, ensuring clear identification. It also references the Welding Procedure Specification (WPS) number, which outlines the standards for the welding process. The form details various qualification test parameters, including the type of welding process—whether manual, semiautomatic, or automatic—as well as the base metal specifications and thickness. Furthermore, it records the filler metal specifications and any additional materials used, such as penetration-enhancing flux. The mechanical test results and non-destructive examination outcomes, including radiographic results and visual inspections, are also documented to validate the welder's capabilities. Finally, the form includes certification statements, ensuring compliance with industry standards, such as AWS D1.1, and is signed by a qualified individual, solidifying its authenticity. This comprehensive record not only demonstrates a welder's proficiency but also serves as a crucial reference for employers and regulatory bodies alike.

More PDF Templates

Warranty on Roof - Always consult MCS Roofing before making any changes to your roof.

To create an effective Florida Non-disclosure Agreement (NDA), it is essential to utilize a form that meets specific legal standards and guidelines. This document ensures that sensitive information remains confidential and is not shared without permission, providing peace of mind for individuals and businesses alike. For those looking to access the necessary template, you can find it at https://floridaforms.net/blank-non-disclosure-agreement-form/, ensuring compliance with Florida laws while safeguarding valuable intellectual property.

Socialsecurity611 - This form is vital for any beneficiary experiencing a drop in financial resources.

Document Specifics

| Fact Name | Details |

|---|---|

| Purpose | The Welder Performance Qualification Record form certifies a welder's ability to perform welding tasks according to specific standards. |

| Welder Information | It requires essential details about the welder, including their name, ATF number, and Social Security number. |

| Welding Process | Different welding processes can be specified, such as manual, semiautomatic, mechanized, and automatic. |

| Base Metal Specification | It includes the base metal specification, thickness, and diameter, which are critical for qualification. |

| Mechanical Testing | Results from mechanical tests must be documented, confirming the quality and strength of the welds. |

| Non-Destructive Examination | The form requires results from non-destructive tests, such as radiographic testing and visual inspections. |

| Certification | Certification is provided by a Certified Welding Inspector (CWI), ensuring compliance with industry standards. |

| Governing Laws | In many states, the AWS D1.1 code governs the qualification process for welders. |

| Validity | The form must be completed accurately and signed to be valid for future employment and projects. |

How to Write Welder Performance Qualification Record

Completing the Welder Performance Qualification Record form is a crucial step in documenting a welder's skills and qualifications. This form captures various details about the welder, the welding process, and the results of tests conducted. Following the steps below will help ensure that the form is filled out accurately and completely.

- Begin by entering the Welder’s Name in the designated space.

- Fill in the ATF No and Test No fields.

- Provide the Welder’s SS No (Social Security Number).

- Write the Date of filling out the form.

- Enter the Reference WPS No (Welding Procedure Specification Number).

- Specify the Code or Specification Used for the qualification.

- Select the Welding Process and Type from the options provided (Manual, Semiautomatic, Mechanized, Automatic).

- Indicate whether Backing was used or not.

- Fill in the Base Metal Spec/P or M-Number and the thickness for Plate/Pipe (Groove and Fillet).

- Provide the Outside Diameter for Pipe/Tubular (Groove and Fillet).

- Enter the Filler Metal Specification No and Classification No.

- Specify the F No. and Diameter of the filler metal.

- Indicate if a Consumable Insert was used.

- State whether Penetration Enhancing Flux was used.

- Provide the Deposited Weld Metal Thickness.

- Fill in the Current/Polarity & Current Range (Type/Polarity and Range in Amperes).

- Specify the Metal Transfer Mode (GMAW or FCAW).

- Indicate the Torch Shielding Gas Type and Flow.

- Provide details for the Root Shielding Gas if applicable.

- List the Test Position(s) (1G, 2G, etc.) and Qualified Position(s) (F, H, V, O, or All).

- Indicate the Vertical Progression (Uphill or Downhill).

- Complete the MECHANICAL TEST RESULTS section, including type and results.

- Fill in the Guided mechanical Testing Conducted By and Date.

- Complete the NONDESTRUCTIVE EXAMINATION RESULTS section with Radiographic Results and Report No.

- Indicate who conducted the Radiographic Testing and who witnessed the welding.

- Complete the Visual Inspection results (Pass/Fail and reason if applicable).

- Certify the statements in the record by providing the Date Qualified, ATF Name and Number, and Signed By (CWI No.).

Dos and Don'ts

When filling out the Welder Performance Qualification Record form, it’s important to be thorough and accurate. Here are some guidelines to help ensure the process goes smoothly.

- Do provide the welder’s full name and correct identification numbers.

- Do check the reference WPS number for accuracy.

- Do clearly indicate the welding process and type used.

- Do specify the base metal specifications and thickness accurately.

- Do include details about the filler metal specification and classification.

- Don’t leave any required fields blank.

- Don’t use abbreviations that may not be understood by others reviewing the form.

- Don’t forget to verify the results of mechanical tests and inspections.

- Don’t sign the form until all information is complete and accurate.

- Don’t overlook the importance of having the form reviewed by a certified welding inspector.

Following these guidelines will help ensure that the Welder Performance Qualification Record is filled out correctly, which is essential for maintaining compliance and quality in welding practices.

Documents used along the form

The Welder Performance Qualification Record form is essential for documenting a welder's skills and capabilities. Alongside this form, several other documents play a crucial role in the qualification and certification process. Below is a list of commonly used forms and documents that complement the Welder Performance Qualification Record.

- Welding Procedure Specification (WPS): This document outlines the specific welding processes and parameters to be followed during welding. It includes details such as the type of materials, welding techniques, and safety measures.

- Procedure Qualification Record (PQR): The PQR verifies that a particular welding procedure can produce welds meeting the required standards. It includes results from tests conducted on welds made according to the WPS.

- Welder Certification Card: This card serves as proof that a welder has successfully completed the necessary training and passed the required tests. It typically includes the welder’s name, certification number, and expiration date.

- Inspection Report: This report documents the results of inspections performed on welds. It includes findings from visual inspections and any non-destructive testing that was conducted to ensure weld integrity.

- Vehicle Purchase Agreement: This important document outlines the terms of sale for a vehicle, safeguarding both the buyer and seller by detailing aspects such as purchase price and vehicle identification. For a comprehensive template, visit California Templates.

- Test Record: The test record provides detailed results of the qualification tests performed on the welder. It includes information such as the type of tests conducted, the results, and any observations made during the testing process.

These documents work together to ensure that welders meet industry standards and maintain high-quality workmanship. Proper documentation not only enhances safety but also fosters accountability in the welding profession.